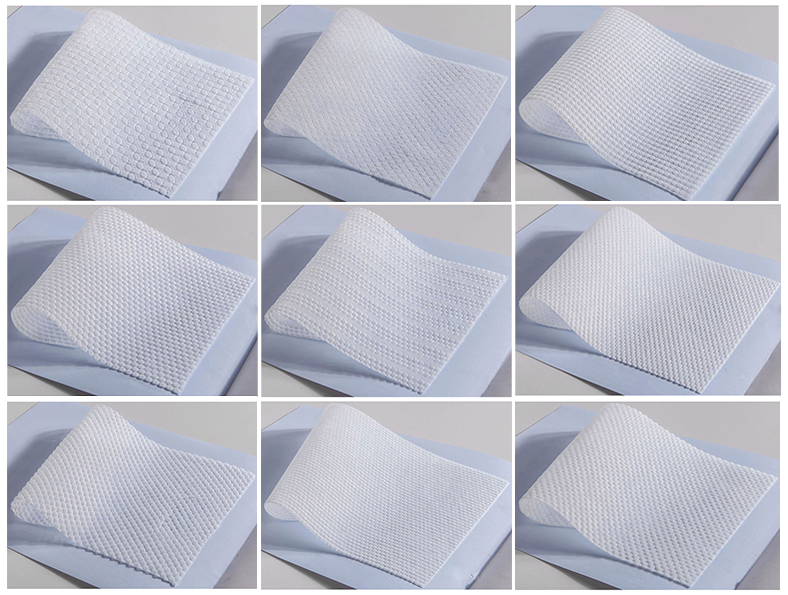

Hydrophilic perforated nonwoven fabric serves as the diaper's surface layer, offering softness and breathability. It quickly absorbs liquids, minimizes backflow, and keeps the baby's skin dry. Crafted with safe, skin-friendly materials, it gently cares for sensitive skin, ensuring breathable, hypoallergenic comfort.

item no.:

diaper raw materialsPayment:

T/T; L/Cproduct origin:

ChinaColor:

whiteshipping port:

XiamenLead Time:

15-20daysBaby Diaper Top Sheet Nonwoven Perforated Nonwoven

Quick Details

|

Type |

Spun bond |

|

10-35gsm |

|

|

Tensile strength (MD) |

12-35N/5 cm |

|

Tensile strength (CD) |

3.5-12N/5 cm |

|

Elongation (MD) |

15-70% |

|

Elongation (CD) |

30-90% |

|

Normal strike-through time |

<3 sec. |

|

Rewet |

approx. 0.13g |

|

Run off |

0% |

|

Specific gravity |

0.9 |

Multi-aperture·Customizable——Tailored perforation solutions for your unique product needs!

Unique Properties

SSS polypropylenetopsheet nonwoven for baby diaper raw materialsis made of 2 layers

polypropylene Spun-bond, which is consist of continuous super-fine filament, with good uniformity, good tensile strength and elongation.

Hydrophilic diaper vtop sheet Nonwoven Fabricis very light andpolypropylene is the main raw material.

Hot salediaper Nonwoven Fabricisfleecy and touches well, giving softness to babies’ skin.

Baby diaper used nonwoven fabrichas great filtering and breathable capacity, offering comfort for babies.

High quality Hydrophilic Nonwoven Fabrichas excellent flexibility because it is made up of microfiber (2-3D) and DOT by DOT thermo-melt formed.

SSS diaper top sheet Nonwoven fabricperforms well in diffusivity and water absorption.

The role of hydrophilic Nonwoven in baby diapers

Hydrophilic nonwoven fabricused in baby diapers is the main top sheet, the top surface that is in contacts with the baby’s skin. It allows the liquids to flow into the diaper core. The surfactant treatment in nonwoven reduces the surface tension of the nonwoven, reduces the contact angle with the liquid and allows it to pass. Flow dynamics within the diaper core prevent liquids from returning to the surface.

Production Process

Customized service process

1. Requirements communication: Hole shape/density/gram weight/color

2. Proofing test: Sample delivery within 3-5 working days

3. Mass production delivery: support small batch flexible orders

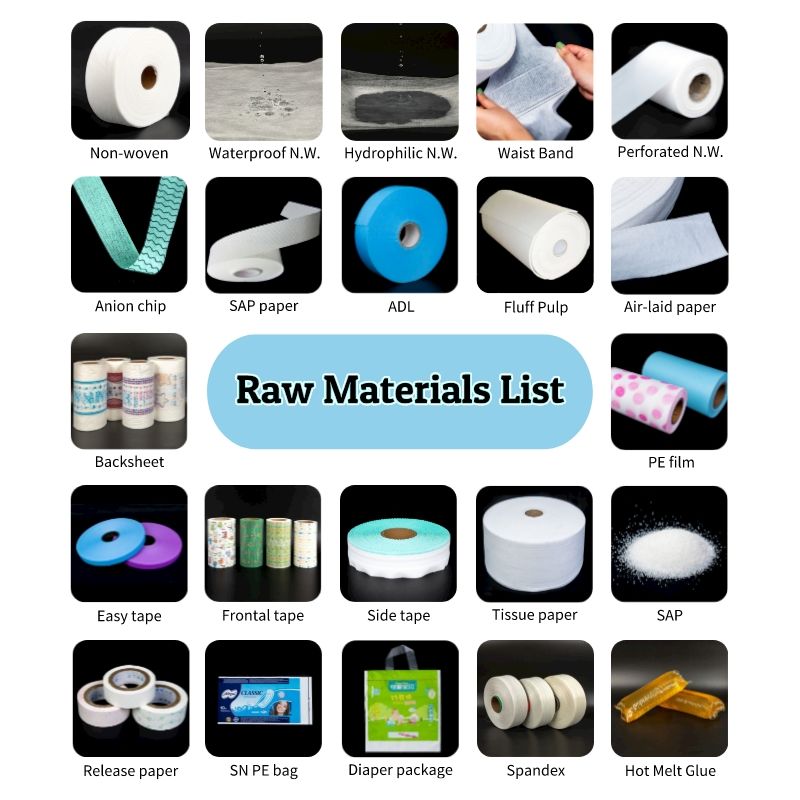

Other raw materials are available

Quanzhou Niso Industry Co.,Ltd is your best choice for diaper raw material, sanitary napkin material and disposable hygiene products in China.